- Home

- /

- Applications

- /

- Advantages of Drintec™ Upflow Contactors

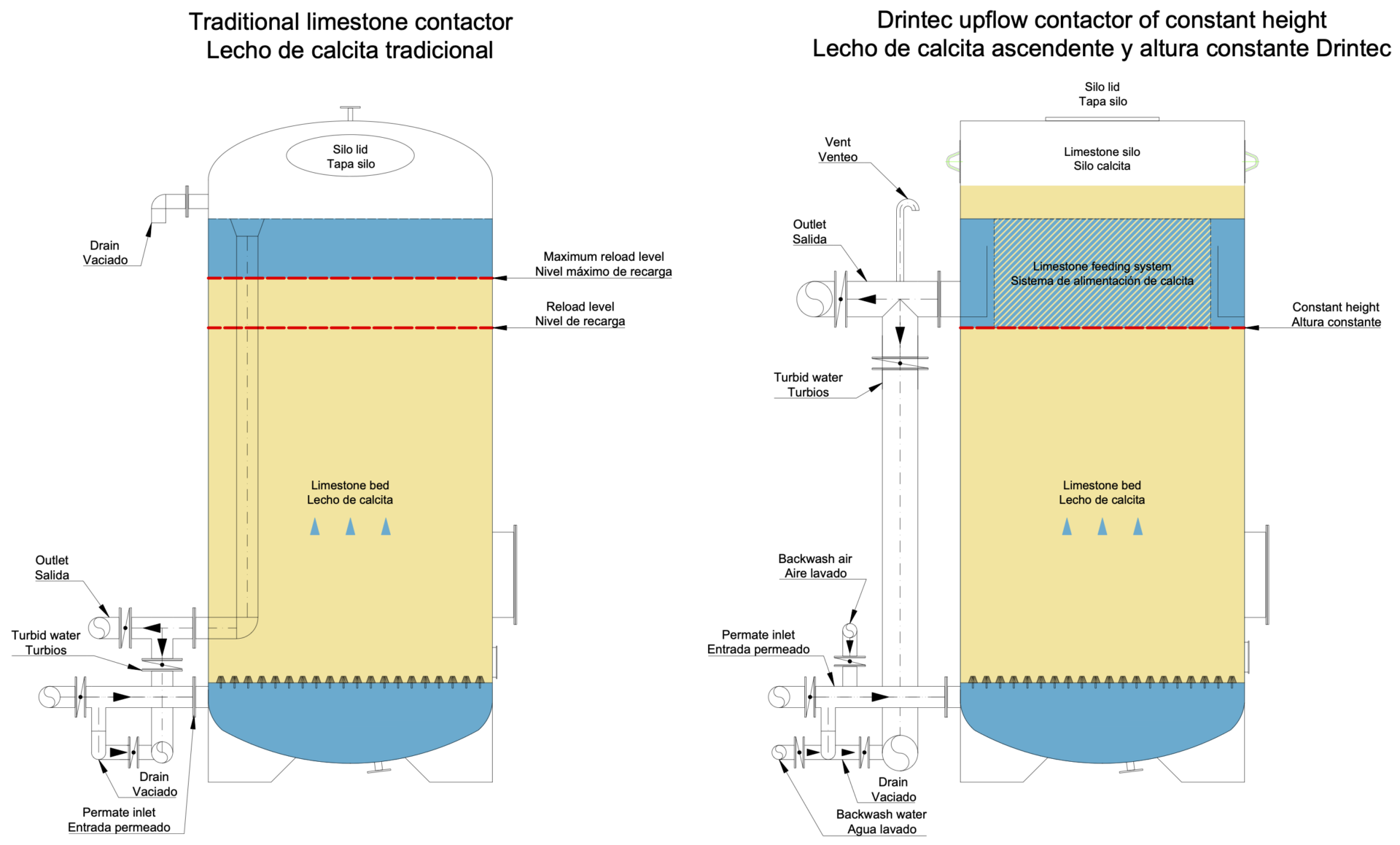

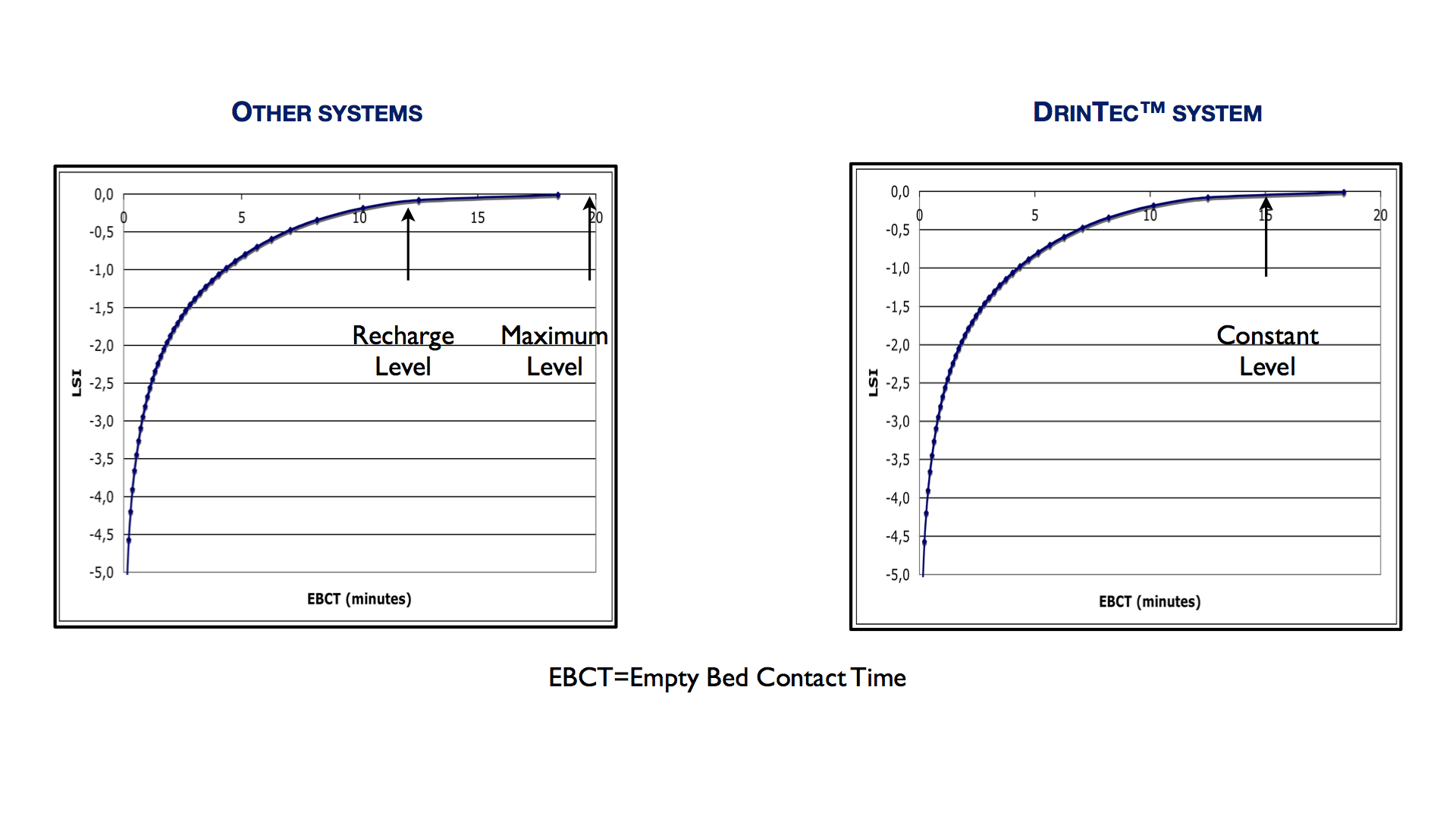

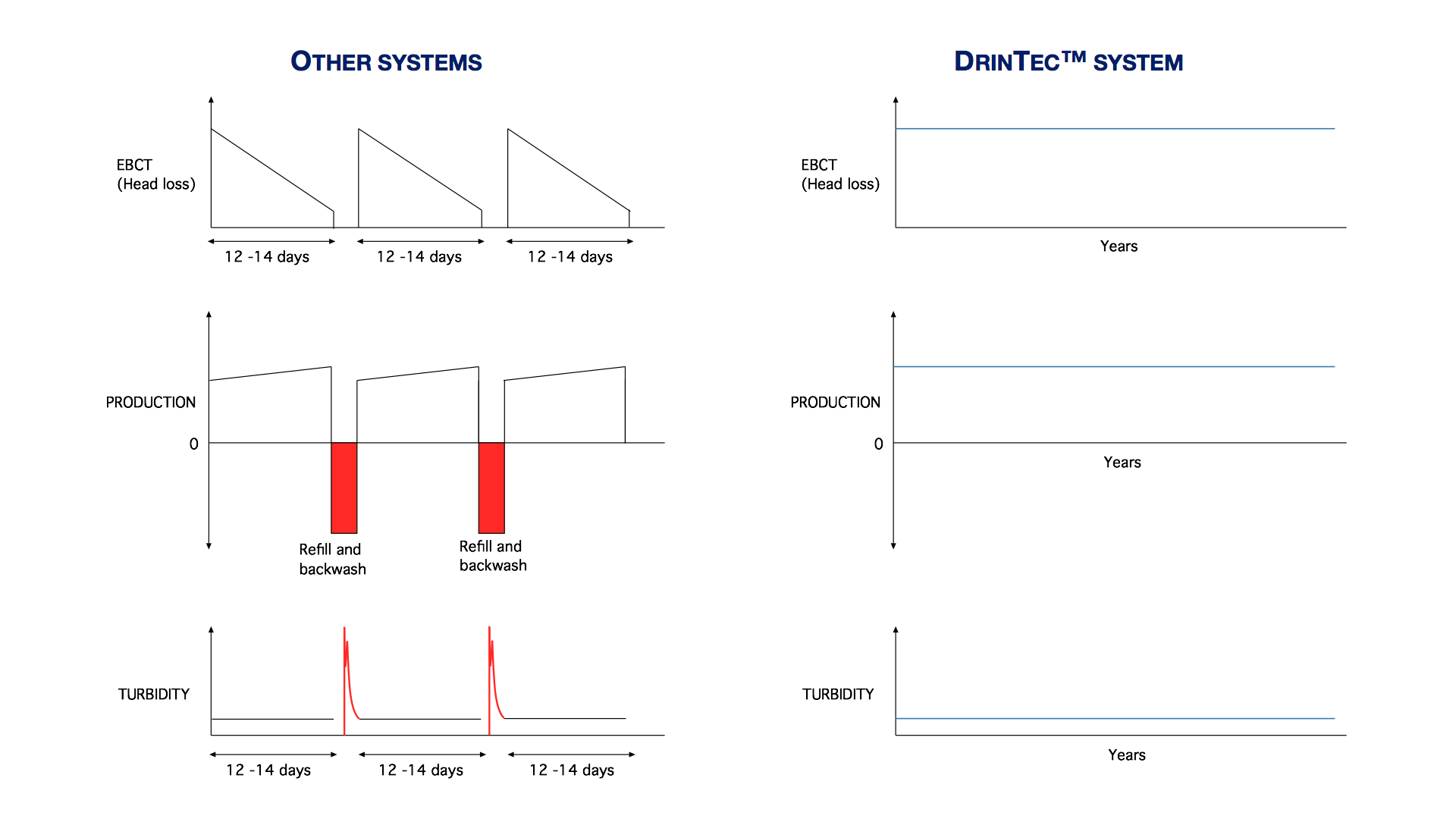

Drintec™ Upflow Limestone Contactors vs Traditional Limestone Contactors

Main advantages and disadvantages of Drintec™ Upflow Contactors.

| Contactor type | Advantages | Issues to consider |

|---|---|---|

| DrinTec™ upflow contactors of constant height |

|

|

Main advantages and disadvantages of Traditional Limestone Contactors.

| Contactor type | Advantages | Issues to consider |

|---|---|---|

| Traditional Limestone Contactors |

|

|

Diagram showing differences between Drintec™ Upflow Limestone Contactors vs Traditional Limestone Contactors